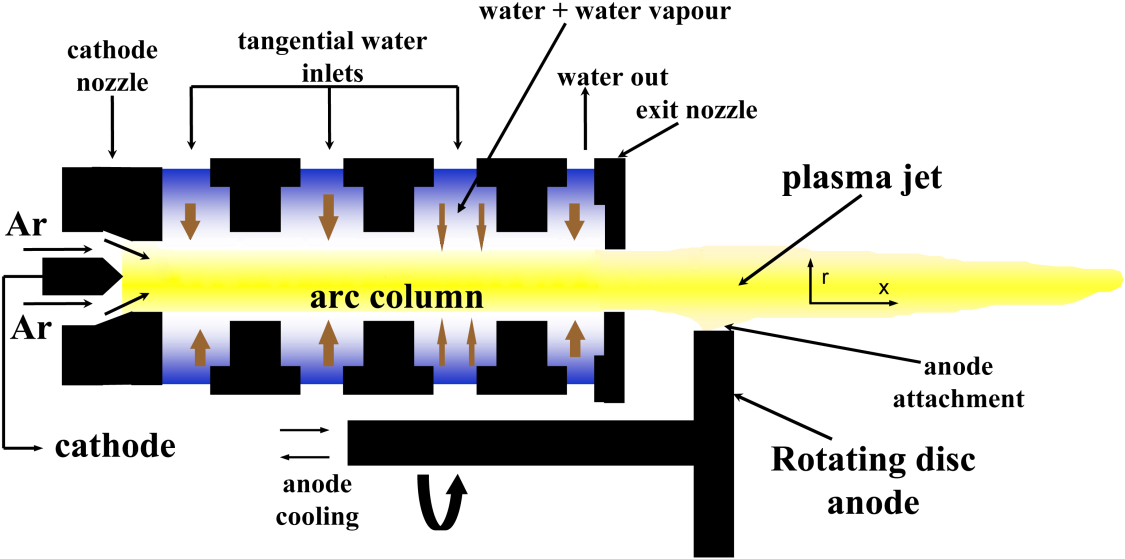

WSP-H torch scheme.

Example of enthalpy contours near outlet region for 500A and 15 slm of argon. Steam mass flow rate is 0.329 g/s.

Torch specifications (WSP-H 500)

*typical values depending on the configuration of the torch

- Operation power: 100-180 kW

- Arc current: 350 - 600 A

Argon flow: 12 - 35 slpm

- Water consumption: ~1 liter per hour

- Plasma characteristics at the exit nozzle:

temperature: up to 25 000 K

- velocity: up to 7000 m/s

- enthalpy: up to 320 MJ/kg

- Feed rates (typical values - not technological maximum):

up to 700 g/min for powders

- up to 150 ml/min for suspensions and solutions

- Arc ignition with electrical impulse

- Long cathode life time allowing long continuous operations

Integrated system

The WSP-H torch is a complete spray system designed for heavy-duty industrial spraying.

It comes fully equipped with all necessary components including:

- DC power supply.

- Water system with process feedback control.

- Water coolers.

- Modern software tailored for day-to-day easy use.

- Spraying parameter library and remote online helpdesk.

- Automated powder injector positioning system supporting up to 3 feed lines (optional).

- Set of consumables.

- Any standard powder feeder(s) capable of delivering requested feed rates can be integrated. Combination of several standard feeders is often used for extreme throughputs.

Dedicated feeder for spraying liquid NEW

WSP-H system may be now equipped with

dedicated 2nd

generation liquid feeder, which was designed to inject suspensions and

solutions with high feed rates (up to 300 ml/min).

Selected features:

- On-line flow rate control (Coriolis

flow meter).

- Pneumatic operation (pressure up to 8 bars).

- 3 x 5 liters containers for continuous

deposition or spraying composite materials.

- Stirrer and peristaltic recirculation preventing suspension sedimentation and clogging.

- Remote touchscreen control from your mobile or PC.

- Suspensions with up to 75 wt.% solid load were successfully sprayed.

- Setup is customizable upon customers request.

- May be combined with powder spraying - "hybrid concept".

- Compact design.

- Can be sold separately to support your current torch.